By Steve Binkley

InfoStream Safety Consultant

The Commercial Vehicle Safety Alliance (CVSA) released their 2021 International Roadcheck results. For many of the inspectors, it was a repeat performance from previous years.

During the 72-hour inspection blitz, held in May 2021, inspectors examined more than 40,000 commercial vehicles at inspections sites in Canada, Mexico, and the U.S. After discovering out-of-service violations, inspectors called for the removal of 6,710 commercial motor vehicles and 2,080 drivers from the roadways. Mexico performed vehicle-only inspections.

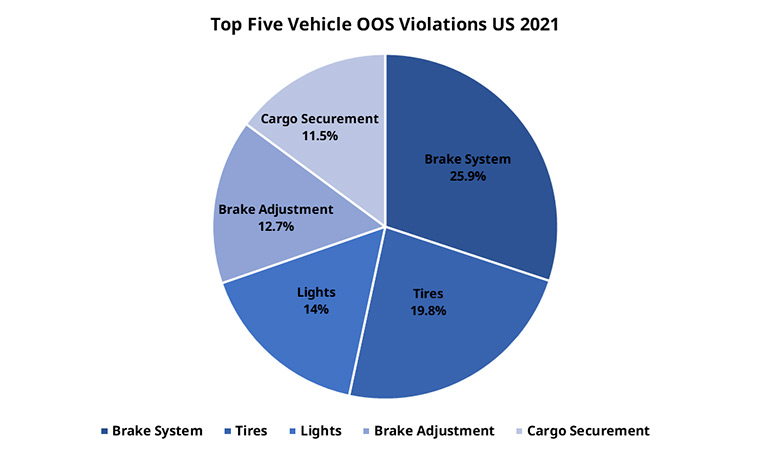

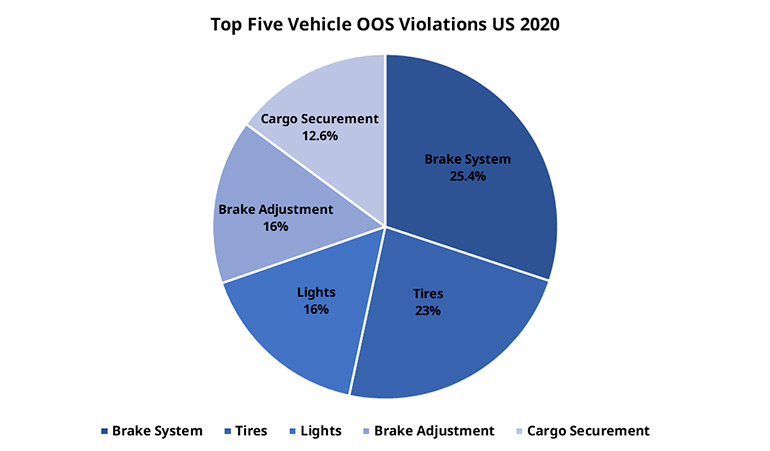

Of the 40,000 inspections, 21,135 were level I – the most thorough inspection completed. The CVSA reports that 83.5% of the commercial motor vehicles examined had no out-of-service (OOS) violations. However, the roadcheck documented some familiar out-of-service defects. Below is a 2-year comparison of the United State’s inspection performance charts released by the CVSA.

The results and percentages look familiar:

Source: https://www.cvsa.org/news/2021-roadcheck-results/

Source: https://www.cvsa.org/news/2020-roadcheck-results/

When we compare these results, we’ll see similar percentages. I have questions about how motor carriers and our industry could prevent these violations, and we need to be part of the solution:

Lighting defects happen, but we can better manage these defects by issuing light kits to drivers and using the safety lanes at terminals. Have more eyes to look for defective lights before trucks leave the terminals and urge drivers to report defects.

In 2020, the Federal Motor Carrier Safety Administration reported that “inoperable required lamp” was the number one vehicle violation, nearly 12% of all vehicle violations found.

Cargo securement violations can vary, but we must remain vigilant to improve performance. Inspectors look for damaged systems that secure the cargo, and they note the number of tie-downs used. They look at dunnage and other securement supplies and will report when they’re not adequately secured. Correcting these violations is quickly done with proper securement training. Carrier operations guidance should require drivers to do routine inspections during their scheduled stops.

Proactive maintenance and driver training can eliminate many out-of-service defects. Having consistent maintenance schedules, investing in technology, and training drivers on maintenance and operations helps them know what to look for and when to call a time out. It’s time our industry fixes these repeat violations.

A proactive approach makes our industry safer; it’s time we greatly reduce the number of violations and significantly lessen the out-of-service percentages we get from this yearly inspection exercise. I, too, want to see familiar numbers but in significantly reduced out-of-service rates.

Steve Binkley is a safety professional with 38 years of experience, including 26 years with the Tennessee Highway Patrol, where he retired as captain of the Commercial Vehicle Enforcement division. He also worked as an associate instructor with the Federal Motor Carrier Safety Administration National Training Center and vice president of safety at a large-tier motor carrier. Today, Steve serves as a safety and compliance consultant/instructor at North American Transportation Management Institute and speaks publicly about trucking safety.